TECHNICAL PACKAGING

다양한 고객 니즈에 맞춰 포장 품목의 기능과 상태를 보호하기 위해

반복사용이 가능한 케이스와 완충재(Foam 또는 Frame)를 활용한 솔루션

반복사용이 가능한 케이스와 완충재(Foam 또는 Frame)를 활용한 솔루션

보유역량

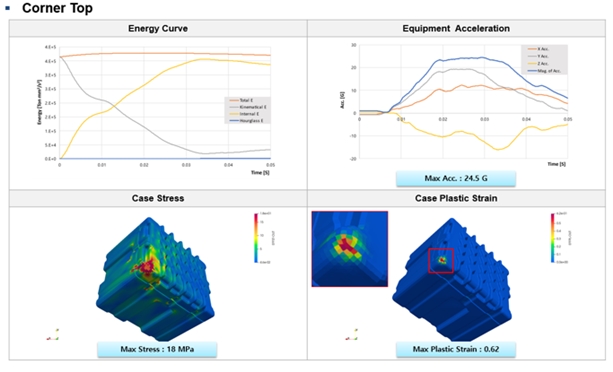

※ 설계 및 연구인력 확보, CATIA / ANSYS 등 분석 프로그램 활용

피로분석

구조해석

환경시험

저온/고온, 충격,낙하, 진동, 살수, 침수시험 등

3D 모델링

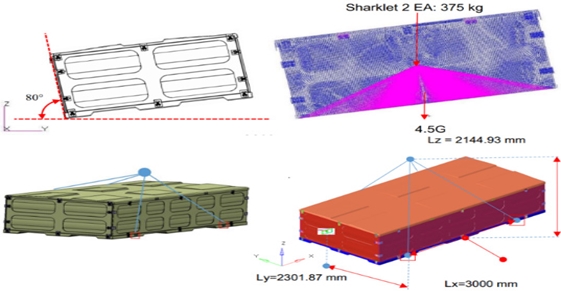

육군 KCTC 마일즈

대형 불출함 국산화 완료

대형 불출함 국산화 완료

- 우수상용품 시범사용 추진

- 육ㆍ해ㆍ공 마일즈 훈련체계 사업화 추진

KF-21 다목적 포장용기(7종)

국산화개발

국산화개발

- 시제품 개발 및 환경시험 완료, 도면 최신화 등 규격화 추진

- KF-21 LRU 22품목 케이스(5종), 지원장비용 케이스(2종) 관련업체 공급

유통브랜드

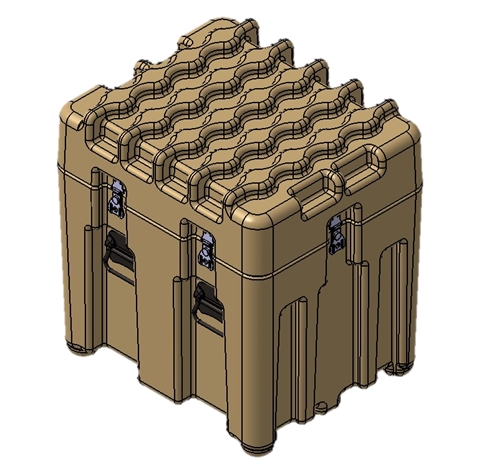

패키징(Case)

내부 완충재 설계 및 제작을 기반으로 한 패키징 솔루션

화공 및 도료 제품(CHEMICAL)

접착제, 필름, 실란트, 프라이머 등 항공 부자재 유통

케이스 맞춤형 폼 가공

GV 경쟁력

완충재 설계능력 확보

2D, 3D 설계 프로그램 / 전문인력 확보

도면 및 기술자료 작성 역량 보유

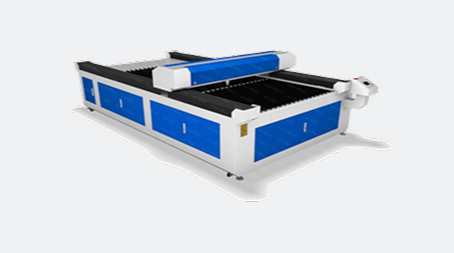

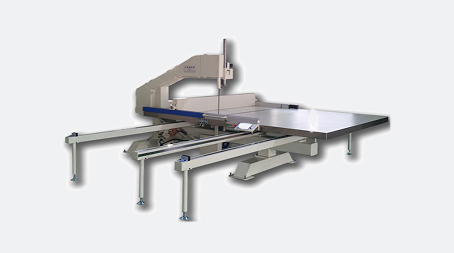

레이져 조각기

고객요구사항 충족

사내 가공 및 제작

형상, 규격 변경시 즉시 대응 가능

⇒ 소요시간 / 비용 최소화

⇒ 소요시간 / 비용 최소화

수직 절단기

고도의 품질보증

다양한 납품실적

각종 기술자료 제공

(COC, 도면, 검사성적서 등)

(COC, 도면, 검사성적서 등)

체계적인 이력관리

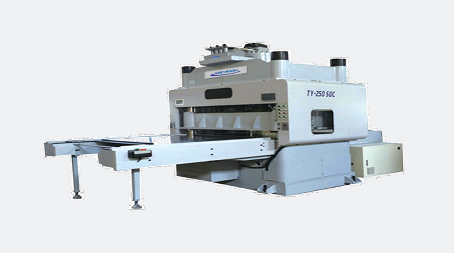

압축 프레스

HOME

HOME